The History of the Company

|

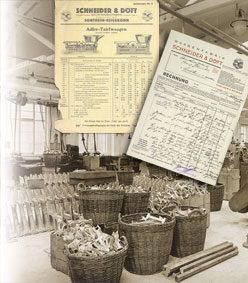

The company was founded in 1875 in Heilbronn by Franz Schneider Senior as a precision engineering workshop. In the beginning, it dealt with the repair of high tech products, bicycles and sewing machines. In subsequent years the production of prescision weighing scales was commenced. In 1890, weighing scale production was expanded. The company moved to a new building in Sontheim near Heilbronn. With the beginning of the new century - in 1901 - Franz Schneider Senior and Döft Brothers became partners. The company was changed into a general partnership and the product program was enlarged. Apart from weighing scales and taps the production of valves began. Furthermore, first supplies of metal parts to the automotive industry were made. In 1906, the production was expanded by a metal foundry for brass and gunmetal parts for the valve production. In 1920, Franz Schneider Junior took his father's place and assumed the direction of the company.

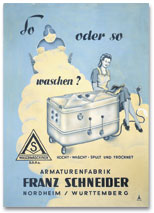

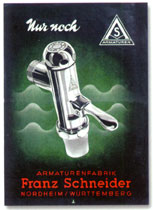

In 1937, the production of valve products and parts commenced in Nordheim with 35 employees. During the subsequent years, the processing of custom designed parts enlarged the product range. The corporate form was changed in 1940 after the sudden death of Franz Schneider Junior. Paul Rhein Senior and Otto Schneider were then appointed as general partners. During World War II, they manufactured, amongst other things, magnesium parts for the aircraft industry. During that time, the staff increased to 90 employees. The new beginning after the end of the war, in July 1945, proved to be extremely difficult, as was the case with many other German companies. The company used its experience in metal processing to produce articles that had become scarce in Germany, as a result of the war – articles for daily use such as lighters, kitchen sieves, sealing machines for tins, taps and other sanitary valves. In 1948, after the monetary reform, supplies to the automotive industry that had begun decades previously were recommenced and intensified. At first, the manufacturing of motor parts for the development and racing departments of this industry was started. Later - in 1950 - turned parts, strainers and general processing parts for serial production were also manufactured. During the fifties, completely new steps were taken in product development and manufacturing. Schneider Armaturen developed and produced a washing machine, but this product was abandoned after a short time. The production of valves proved to be more successful. Gradually the market position was consolidated. In the fifties and sixties, the main emphasis was put on products for the sanitary range. In the subsequent years, however, the situation changed in favour of the instrumentation products for industrial purposes. The premises in Nordheim eventually became too small resulting in cramped working conditions. During the sixties, a branch was built in Ilfsfeld for the production of metal parts and strainers. However, over the next two decades, the industrial area in Nordheim expanded and so it was decided - due to the cost situation - to concentrate the whole company in Nordheim. |

|

|

For this reason, a new production plant was built in 1986 in Nordheim and the production transferred from Ilsfeld.

The location in Ilsfeld was abandoned; the building and plot of land were sold. Eventually the production area became too small again and in 1999 another factory of 1,200 square meters was constructed. |